What does Pawfect Edge do?

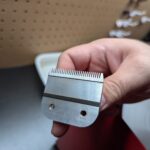

The first step we take once we know a blade is ready for service is calibration.

We check the springs first to make sure the blades springs are at the right pressure.

We want to make sure the blade will cut at the proper spring tension to keep the blade running at top performance to keep the wear on the clippers and blades at a minimal.

This reduces friction, which means your blades run cooler for a longer period of time.

If the tension is too tight or too loose, we adjust it to make sure it is properly set.

We do this before sharpening the blades so we can inspect the wear on the blade while calibrating the tension.

We can tell by looking at the blades wear if it has been running well at this tension, or if adjustments will help the blade.

Then we will adjust the springs accordingly. Once we have taken the blade apart, we will check the socket as well.

When we check the socket we are making sure 3 things are in order.

First, that the little "ears" on the socket are not bent out and are aligned.

Second, we make sure the socket base is also properly aligned and not worn out.

The final thing we check is to make sure the socket is strong. If the socket is worn out and the metal has become loose, this will cause the drive of the clippers to throw the blade back and forth, causing both a cutting issue, and a noisy vibration.

This will in the long run cause undue strain and damage to both your clippers and the blade itself.

If the socket is damaged, it can be replaced, and we will let you know if it is needed.

The comb and cutter of the blade is ready to be sharpened at this point. We pass the pieces over the wheel to sharpen the rails.

After the initial pass, we examine the rails. In this case the blade had a lot of wear, and would require an additional pass on the wheel.

As you can see, after the second pass the rails are now well sharpened and you can see the shiny sharpened surface.

We then repeat the process with the cutter side of the blade.

After the pieces are sharpened, we demagnetize them to remove all of the burrs that occur during the grinding. Burrs are tiny shards of metal left over from the sharpening process. This makes sure there are no tiny burrs between the teeth that will damage the recently sharpened surface.

We then give the blades a scrub in our degreasing solution to give them a nice deep clean and remove any debris stuck onto the blades.

After we scrub the blades we use high pressure air to blow the blades completely dry to keep the blades from rusting.

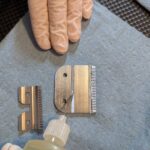

Now the blades are ready to be reassembled. We start by applying a small line of starter oil on the rails of the comb.

We then place the socket and spring together and apply the screws.

We then make sure the cutter is perfectly aligned on the rails, and tighten up with screws completely, leaving the blade perfectly assembled.

After the blade is fully assembled we do a string clip test to check the blades cutting ability. When a blade is sharpened properly, you will have a clean sharp cut on the string without fraying.

If requested, we will then do a full 5 point oiling on the blades. This is optional as some people prefer to oil their blades themselves, and just want the initial starter oil applied. If you do not have us fully oil the blades, please do remember to oil them completely before the first use.

We then place the freshly cleaned and sharpened blades in your complimentary blade box and return them to you like new and ready to go.